Chlorinated Polyethylene CPE Resin Manufacture

CPE resin is a polymer material made of high-density polythene resin through chlorination reaction. According to its application, VIA Chemical CPE resin can be classified as CPE for plastic impact modification and CM for rubber.

CPE Resin Product Types

We offer four different CPE products that can be applied in plastics, cables, and cord fields. Moreover, we can customize and produce CPE and CM according to your specific requirements.

ITEM | GRADE AND INDEX | |

CPE135 | CM135 | |

Chlorine content % | 35±2 | 35±2 |

Enthalpy of Fusion(J/g) ≤ | 2.0 | 2.0 |

Volatile content/% ≤ | 0.40 | 0.50 |

Screenings(0.9mm sieve mesh)/% ≤ | 2.0 | - |

Impurity particles/(pieces/100g) ≤ | 50 | - |

Ash content /% ≤ | 4.5 | 4.5 |

Mooney viscosity ML (1+4)125℃ ≤ | - | 100 |

Elongation at break /M Pa ≥ | 8.0 | 6.0 |

Shore hardness(Shore A)≤ | 65 | 60 |

*The above specifications are provided for reference only. Products could be produced per client’s requirements.

Chlorinated Polyethylene CPE Resin Features and Applications

Good impact resistance modifier with flexibility

Good chemical resistance

Good flame resistance

Excellent temperature and weather resistance

Excellent processing performance

Good filling ability

Good compatibility with polyvinyl chloride (PVC), polyethylene (PE), and Acrylonitrile butadiene styrene (ABS)

CPE is an excellent and cost-effective impact modifier and can significantly improve the impact strength and temperature resistance of rigid plastic pipe and fittings.

CPE has good flame resistance and is compatible with ABS. Thus, it can be used to make ABS flame resistant.

CPE is also widely used in semi-rigid and soft plastic products. As a non-migratory plasticizer for macro molecule, it can improve the product flexibility and aging and temperature resistance.

Chlorinated Polyethylene CM Features and Application

Good chemical resistance and machine oil resistance

Good low-temperature flexibility and flame resistance

Good thermal aging and weather resistance

Good bending resistance

CM can be mixed with chloroprene rubber (CR) and nitrile rubber (NBR) to improve their performance and can also be used alone as special rubber.

Chlorinated Polyethylene CM can be used for producing high-grade waterproofing coiled materials and magnetic rubber, among others.

Chlorinated Polyethylene CM can be used for producing cables and cord sheaths (mine, marine, and locomotive cables), conveyor belts, corrosion-resistant sealing, and rubber hoses for cars (such as oil-conveying pipe, AC hose and brake and steering fluid conveying pipe), rubber dams, and rubber track plates, among others.

Chlorinated Polyethylene CM has good filling characteristic for iron oxide magnetic powder; the magnetic material with CM will have low temperature flexibility. Thus, it is widely used as a sealing strip for refrigerators and magnetic cards, among others.

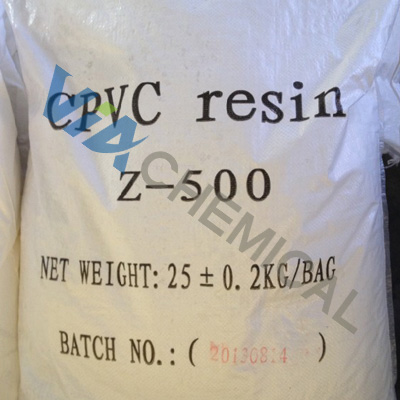

CPE Resin Packing and specification

VIA Chemical CPE product adopts polyethylene bags for internal use and polypropylene bags for external use with a net weight of 25 ± 0.2 kg per bag.

CPE Resin Storage and transportation

CPE resin must be stored in a dry and ventilated warehouse with a stack height not exceeding 10 bags. Solarization and damp environments should be avoided and strict precautions should be taken again stress. CPE is not considered a dangerous cargo.

CPVC J-700

CPVC Z-500

CPE 135A